Published 2011-03-30

abstract views: 367 // FULL TEXT ARTICLE (PDF): 0

Keywords

- Lean Production,

- Line Output Improvement,

- 5S,

- Line Time Study

How to Cite

Copyright (c) 2023 International Journal of Industrial Engineering and Management

This work is licensed under a Creative Commons Attribution 4.0 International License.

Abstract

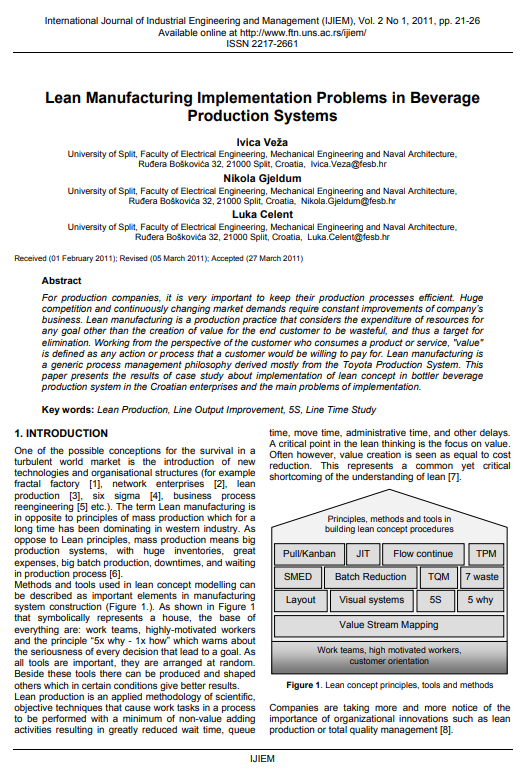

For production companies, it is very important to keep their production processes efficient. Huge competition and continuously changing market demands require constant improvements of company’s business. Lean manufacturing is a production practice that considers the expenditure of resources for any goal other than the creation of value for the end customer to be wasteful, and thus a target for elimination. Working from the perspective of the customer who consumes a product or service, "value" is defined as any action or process that a customer would be willing to pay for. Lean manufacturing is a generic process management philosophy derived mostly from the Toyota Production System. This paper presents the results of case study about implementation of lean concept in bottler beverage production system in the Croatian enterprises and the main problems of implementation.

Article history: Received (01 February 2011); Revised (05 March 2011); Accepted (27 March 2011)